PRODUCT

A product that works! I feel the difference in work efficiency.

One Touch Coupler

One-touch coupler features

- Combined slim push and separate one touch

- Guaranteed 10 times the life of internal structure change

- Domestic distribution of overseas export products

- Production of various models of small and light weight

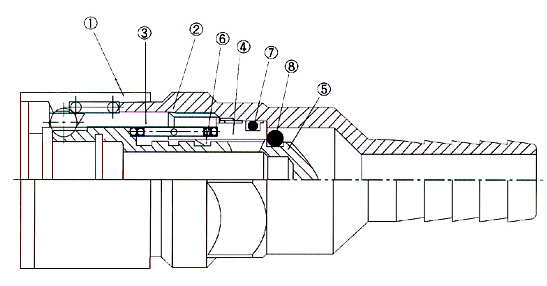

| NO | Name | material | Key Characteristics of Mammoth Quick Coupler |

|---|---|---|---|

| 1 | Cover | Steel | Strong Cover Treatment / External Pressure Response / Rust Prevention |

| 2 | Body | AL D/C Injection | Integration of joints / prevention of intermediate leakage and corrosion |

| 3 | Cylinder Cover | AL D/C | Improved C-Ring into a cylindrical shape / Blocked departure |

| 4 | Sleeve | Acetal | Complete adhesion of body and sleeve / prevention of fluidity |

| 5 | Cylinder | Acetal containing urethane (P.O.M FU2020) |

Integrated cylinder (patent) structure / fundamentally prevents O-Ring separation / Urethane impact and freeze protection |

| 6 | Y-Band | natural NBR | Y-Band applied to cylinder and sleeve / prevent leakage |

| 7 | O-Ring | natural NBR | Natural NBR, more durable than synthetic NBR |

| 8 | O-Ring | natural NBR | Natural NBR, more durable than synthetic NBR |

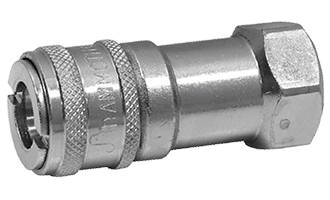

SOCKET

Functional features

- General products are shielded by O-ring when combined with plug, so air pressure leaks when O-ring is damaged.

- Our product is improved to Y-BAND TYPE, and it is a sealed type even when O-ring is damaged, preventing pneumatic leakage.

- O-RIGN material uses synthetic NBR for general products, but natural NBR for its own products.

- Material of SLEEVE

* SOCKET: Reinforced impact hardness by using urethane-containing impact-resistant acetal [prevents freeze in winter]

Characteristics of the manufacturing process

- General products are E-RING or C-RING combination type and are damaged when the E-RING is separated.

- The company's product fundamentally blocks breakaway damage by screwing.

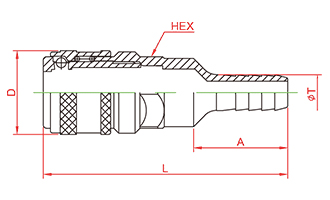

DSH 20 / 30 / 40

| MODEL | T(Φ) | L(m/m) | HEXAGON(m/m) | A(m/m) | D(Φ) |

|---|---|---|---|---|---|

| DSH 20 | 9 | 75.5 | 21.8 × 24 | 25 | 25.5 |

| DSH 30 | 11 | 75.5 | 21.8 × 24 | 26 | 25.5 |

| DSH 40 | 15 | 76 | 21.8 × 24 | 28 | 25.5 |

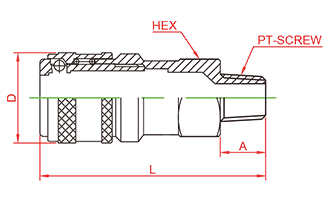

DSM 20/ 30 / 40

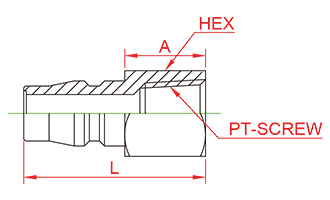

| MODEL | PT-SCREW | L(m/m) | HEXAGON(m/m) | A(m/m) | D(Φ) |

|---|---|---|---|---|---|

| DSM 20 | PT 1/4 | 65 | 22 × 25.2 | 12 | 25.5 |

| DSM 30 | PT 3/8 | 66.6 | 22 × 25.2 | 13 | 25.5 |

| DSM 40 | PT 1/2 | 66.6 | 22 × 25.2 | 14 | 25.5 |

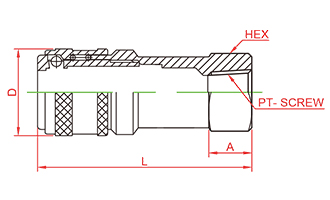

DSF 20 / 30 / 40

| MODEL | PT-SCREW | L(m/m) | HEXAGON(m/m) | A(m/m) | D(Φ) |

|---|---|---|---|---|---|

| DSF 20 | PT 1/4 | 61.8 | 22 × 25.2 | 17 | 25.5 |

| DSF 30 | PT 3/8 | 61.8 | 22 × 25.2 | 17 | 25.5 |

| DSF 40 | PT 1/2 | 61.8 | 24.8 × 27.8 | 17 | 25.5 |

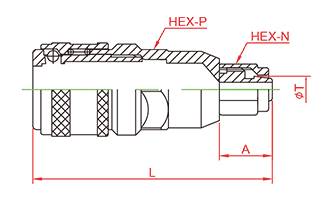

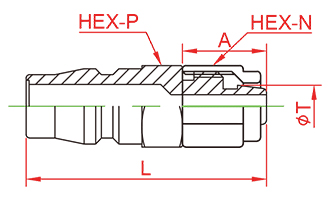

DSN 8 / 10 / 12

| MODEL | T(φ) | L(m/m) | HEX-P(m/m) | A(m/m) | HEX-N(m/m) |

|---|---|---|---|---|---|

| DSN 8 | 7.3 | 64.5 | 21.7 × 24.3 | 14.3 | 14 × 16.3 |

| DSN 10 | 9 | 69.4 | 21.7 × 24.3 | 19 | 19 × 21.6 |

| DSN 12 | 10.7 | 71.2 | 21.7 × 24.3 | 19 | 19 × 21.6 |

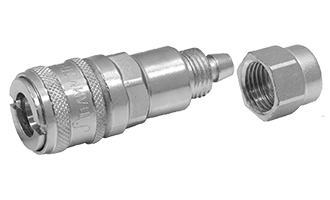

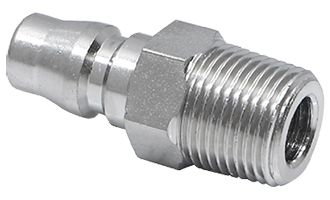

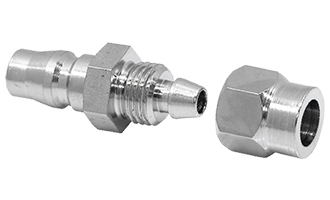

PLUG

Features of PLUG

- Special plug: STEEL, hard chromium plating after heat treatment

- Material: After cold forging of S45C, the functional parts are precisely machined with a CNC lathe. Since the dimensions of the socket insertion part of the plug are the same for all products, the lifespan is better than other products.

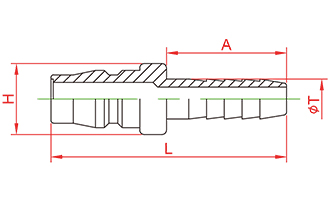

DPH 20 / 30 / 40

| MODEL | T(Φ) | L(m/m) | H(Φ) | A(m/m) |

|---|---|---|---|---|

| DPH 20 | 9 | 53 | 16 | 27 |

| DPH 30 | 11 | 56 | 16 | 30 |

| DPH 40 | 15 | 61 | 18 | 34 |

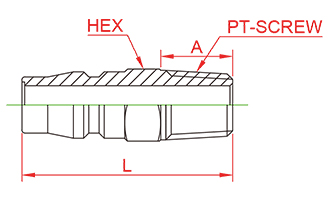

DPM 20 / 30 / 40

| MODEL | PT-SCREW | L(m/m) | HEXAGON(m/m) | A(m/m) |

|---|---|---|---|---|

| DPM 20 | PT 1/4 | 41 | 13.8 × 15.5 | 12 |

| DPM 30 | PT 3/8 | 41 | 17 × 19 | 13 |

| DPM 40 | PT 1/2 | 44.3 | 21 × 24 | 15 |

DPF 20 / 30 / 40

| MODEL | PT-SCREW | L(m/m) | HEXAGON(m/m) | A(m/m) |

|---|---|---|---|---|

| DPF 20 | PT 1/4 | 36 | 17 × 19.3 | 12 |

| DPF 30 | PT 3/8 | 36 | 22 × 25.2 | 13 |

| DPF 40 | PT 1/2 | 36 | 26 × 29.8 | 14 |

DPN 8 / 10 / 12

| MODEL | T(φ) | L(m/m) | HEX-P(m/m) | A(m/m) | HEX-N(m/m) |

|---|---|---|---|---|---|

| DPN 8 | 7 | 44.3 | 14 × 16.1 | 14 | 15 × 17.3 |

| DPN 10 | 8.7 | 46.8 | 17 × 19.6 | 17 | 17 × 19.6 |

| DPN 12 | 10 | 47.5 | 19 × 21.9 | 17 | 19 × 21.9 |